Digital Exclusive: The role of integrated and derisked technologies as a cornerstone of eFuels deployment

Authors: L. COURTAUD, Axens, Houston, Texas (U.S.); C. BRUNN, Axens, Princeton, New Jersey (U.S.); and Y. BERNARD, Axens, Rueil Malmaison, France

Carbon dioxide (CO2) is one of the next-generation feedstocks to produce sustainable fuels and biochemicals. The primary challenges for CO2 conversion have historically included:

- Obtaining sufficient, concentrated CO2 supplies

- Optimizing energy costs and sustainability requirements, including hydrogen (H2) sources, to produce drop-in hydrocarbons

- The lack of fully integrated processes to maximize carbon retention.

As illustrated in FIG. 1, CO2 can be the starting point of many pathways to produce high-value hydrocarbons, including methanol, olefins, ethanol, diesel and jet fuel.1

(click image to enlarge)

FIG. 1. CO2 utilization solutions have many pathways to produce renewable fuels and high-demand petrochemicals.

The authors’ company offers fully integrated, proven solutions to produce fuels from CO2 through the Fischer Tropsch (F-T) and ethanol-to-jet (ETJ) pathways that meet emerging market demand.2 To de-risk clean fuel projects, mature technology developers rely on partnerships and decades of innovation, industrial experience and processes demonstrated in similar or identical services.

Transitioning from fossil-based to renewable feedstocks requires a precise combination of breakthrough technologies and proven commercial processes and products. This approach mitigates project and operating risks (i.e., plant downtime) inherent to new industries and controls liabilities in costs and financing.

CO2 atmospheric emissions reductions involve heavy industries. Reducing CO2 emissions extends beyond fossil fuels. Heavy industries such as steel, pulp and paper, cement, ethanol production, etc., have ambitious plans to shrink their carbon footprints. All major industrial complexes are potential CO2 resources with substantial gas volumes. More importantly, energy transition offers sustainability options for heavy industries, especially where policy support is available.

Solvent-based, gas treating processes are widely used to remove CO2 and other contaminants in the gas processing industry. The adaptation to new industries—including low-pressure absorption—is the key for larger scale deployment.

A significant challenge for the emerging CO2 industry is developing infrastructures to bond CO2 emitters with users. Too often, CO2 emissions sources and utilization plants are not co-located. As a result, delivering concentrated, high-quality CO2 remains difficult. Cost-effective transportation solutions are essential for the long-term success of utilization and sequestration efforts.

More CO2 usage roadblocks. The conundrum is what to do with the captured, concentrated and purified CO2. Possible options include:

- Transportation via pipelines to established CO2 hubs for sequestration

- Liquefaction for other industries

- Use as feedstocks for fuels and chemicals synthesis.

Leveraging CO2 as renewable fuels and chemical resources provides flexible options. Proven technologies support CO2 capture and conversion into revenue-generating products (FIG. 1).3 Using CO2 as a feedstock requires long-term planning and integrating various established process chemistry, decades of knowledge and novel new technologies.

Energy consumption is a processing decision factor. Selecting the most efficient route for an identified market requires careful consideration of processing integration, energy requirements and regulatory compliance (i.e., CO2 source). CO2 is an abundant carbon source, but it has no internal energy. Reusing carbon atoms from CO₂ to form hydrocarbons by combining them with additional H₂ requires significant energy.

The methods for sourcing H2 and meeting energy needs are project dependent. Such approaches include choosing low-carbon electricity or other low-carbon sources. eFuels are produced primarily with electricity, which generates H2 and provides processing energy requirements.

The profitability and success of renewable projects involve risk management, off-take contracts and feedstock supply agreements. Stakeholders include CO2 emitters, unit operators, off-takers and end users. All parties can share both risks and rewards to achieve successful project outcomes in emerging markets. Otherwise, these projects remain promising ideas without any industrial opportunities.

Technologies integration and combination pave Efuels adoption. FIG. 2 shows the integration of proven technologies with breakthrough processes as a reliable roadmap to eFuels through the F-T pathway. Advanced carbon capture/gas treatinga and reverse water gas shift (RWGS)b solutions convert CO2 into quality carbon monoxide (CO). F-Tc,d synthesis transforms CO and H2 into a syncrude.

(click image to enlarge)

FIG. 2. eFuels production through F-Tc,d synthesis is an integrated and electrified pathwaye with great flexibility in feedstock sources and processing routes.

More importantly, this syncrude is further refined via upgrading sections and yields feedstocks suitable for processing into high-value hydrocarbons. With extensive experience in technology licensing, the authors’ company is utilizing decades of knowledge from processing crude oil and applying it to renewable fuel products.

Conventional carbon capture processes are energy-intensive and expensive barriers to the widespread carbon capture, utilization and storage (CCUS) deployment. A next-generation, post-combustion CO₂ capture technologya overcomes the challenges of traditional gas treating.4 The company’s approach uses an innovative “demixing” solvent that significantly reduces energy consumption and captures costs relative to traditional amine-based solvents.

The technologya delivers high-capture efficiencies even with variable flue gas compositions. In particular, this innovationa offers flexible solutions for CO₂ capture. It can decarbonize numerous industries, including steel, cement and aluminum production, as well as energy-related combustion sources. The result is that all heavy-industry sites can deliver concentrated CO2 streams for storage or utilization.

After capture, what is next? The following operational hurdle is converting the captured and conditioned CO2 into CO. The RWGSb,e catalytic process reacts CO2 with H2 and yields CO and water. The authors’ company and Paul Wurth co-developed the RWGSb process and advanced heater/reactor technologye to support market needs and incorporate electrification for energy requirements.

The RWGSb,e process is a high-temperature, endothermic reaction. Consequently, critical thinking balances optimizing energy efficiency and limiting carbon losses through external fuel heating. The advanced RWGSb,e design is a fully electric operation with a novel, new heater technologye.

The innovative reactor refractory design was adapted from the steel industry, which routinely manages the high temperatures associated with converting CO2 to CO. The design reduces energy consumption relative to previous technologies and thus lowers operating costs when combined with in-depth thermal integration.

More importantly, this advanced RWGSb,e process uses commercially available catalysts. The authors’ company’s extensive experience in licensing technologies, combined with Paul Wurth's expertise in high-temperature applications, provides a reliable process block for CO2 utilization.

Long-standing, proven solution finds new purposes. The F-T synthesis is a well-established process historically used for fuel production from coal or natural gas (i.e., WW2). Interest in this process revived with gas to liquid (GTL) applications in the early 2000s. New market opportunities, as part of the energy transition, are once again fueling F-T demand to maximize kerosene (jet fuel) production.

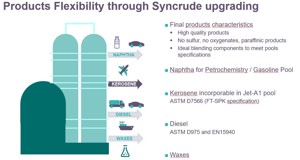

Produced syncrude drop-in for downstream processes. With more than 20 yrs of R&Dc, the authors’ company’s innovative slurry bubble type bed uses a proprietary catalyst. This innovation converts syngas into a high-quality syncruded . As illustrated in FIG. 3, downstream upgrading processes convert the F-Tc,d syncrude into multiple fuels and chemicals.

(click image to enlarge)

FIG. 3. Syngas conversion and syncrude upgrading enlist established hydrocarbon processing technologies to yield green products.

Final products meet industry and transportation standards, specifically ASTM D-7566 for kerosene. The absence of sulfur, nitrogen and aromatics create final product blending values relative to their fossil-based counterparts. Multiple upgrading schemes provide the flexibility to produce a wide product slate, including petrochemical grade naphtha, renewable diesel, sustainable aviation fuel (SAF) and specialty products (waxes or base oils).

Emerging markets will need integrated, de-risked licensed technologies to advance their energy transition programs. Many diverse services support project and operations successes, including studies and engineering, equipment supplies and modular solutions, catalyst supply management and operations follow-up throughout the facility’s life cycle.

Aviation fuel demand is the driving force. Around the world, several announced projects are underway considering biomass, ethanol and vegetables and/or waste oils as renewable feedstocks to meet SAF targets. Among these projects, several consider using CO2 and electrolytic H2 to decarbonize aviation fuels:

- Norske e-Fuel: This is Norway’s first industrial scale eFuel facility.5 The project will use the advanced RWGSb,e process to convert CO2 to CO for F-Tc,d conversion and downstream upgrading units. Also, extensive integration of all processing schemes minimizes the facility’s footprint. The eFuel plant will produce 1,000 barrels per stream day (bpsd) of liquid product from biogenic CO2. Using renewable electricity for energy needs, the finished products meet eFuel submandates of the European regulation, 6

- Take Kair: The Take Kair project is one of the first e-SAF projects in France. Located in Loire-Atlantique, this facility’s feedstock is biogenetic CO2 from nearby cement plants. Take Kair will integrate low-carbon synthesis processingb,c,d and renewable H2 produced by electrolysis. The end product is e-kerosene with a targeted production of 1,200 bpsd of liquid product.

Air France-KLM Group is a project partner as well as the authors’ company, Hynamics, Holcim and IFP Energies Nouvelles.7 This group of partners illustrates the need for a collaborative approach. More importantly, the partners’ diverse expertise and knowledge optimize the value chain of the Take Kair project.

- BioTJet: The BioTJet project is the largest European-based SAF facility. The project design combines gasificationf and F-Tc,d processes to convert lignocellulosic biomass into SAF and renewable naphtha.8,9 BioTJet has support from The French Agency for Ecological Transition. Basic engineering was completed in November 2024 and is now in the detailed engineering phase.

The BioTJet’s carbon feedstock is biomass. In addition, the processing scheme incorporates H2 from electrolysis, allowing it to double the liquids production relative to using biomass alone. Based on EU definitions, roughly half of the product (biomass portion) is classified as “advanced biofuels” and meets the SAF mandate. The second half (H2 portion) is called “renewable fuel of nonbiological origin” and fulfills the e-SAF sub mandate.

Global directives back renewable fuel projects. Initially established for biofuel market development, global mandates have created mechanisms supporting new fuel markets and classes. Net-zero regulations and directives accelerate integrating lower carbon intensity (CI) and renewable fuels into transport and specially aviation fuel supplies and include:

US-One Big Beautiful Bill (OBBB):

- Production credits approach :

- Clean fuel production credits (45Z) until December 2029

- Clean hydrogen production credit (45V) until December 2027

- Carbon oxide sequestration credit (45Q) until June 2026

- Investments, funds and programs

- CI based

EU-Fit for 55 legislation: ReFuelEU policies and RED III update and mandates

United Kingdom: Aviation Fuel plan mandates eFuel

Japan: eFuel regulation under discussion for 2030–2040 implementation

Brazil: “Fuel of the future program” for SAF, synthetic fuel and carbon capture.

Two primary approaches are driving global renewable fuel project activity:

- Incentive programs like those in the U.S. and Canada10

- Mandates, such as those in the EU and UK.6

SAF criteria, quantities and schedule of incorporation vary between countries and regions.

The EU’s ReFuelEU aviation directive imposes a minimum of 6% SAF in aviation fuels by 2030 and 70% by 2050. The objectives of ReFuelEU accelerate investment in SAF production while diversifying technology pathways and feedstocks. In addition, this directive requires eFuels (e-SAF) minimums. Under ReFuelEU, a sub mandate was added and requires aviation fuels to contain 0.7% eFuels by 2030 and 35% by 2050.

Widening CO2 use with reliable technologies. The transition to low-CI fuels relies on a progressive switch from fossil feedstocks to renewables. The emerging eFuels markets increase the possibility to meet emissions-reduction objectives, monetize CO2 use, advance low-carbon electricity and grow demand for clean and concentrated CO2.

eFuel projects face significant economic challenges, particularly in securing affordable, renewable and reliable electricity supplies. However, integrated and reliable technologies from the authors’ company support project developers along their journey to achieve eFuels success.

eFuels and F-T pathways that are fully integrated and electrified solutions (throughout the entire service life of the project, from study phase to turnkey projects) involve:

- Carbon recovery of > 96% single point of contact

- End-to-end guarantees of the integrated solution

- Optimal H2 consumption

- Flexibility: SAF/diesel and more

- Maximized SAF yield.

NOTES

a Axens’ DMX™ carbon capture technologies.

b Paul Wurth and Axens are collaborating in RWGS solutions and reactors that meet electrification requirements. The RWGS is branded by Axens as CarboVerseo™.

c Eni and IFPEN researched the new F-T synthesis technologies.

d Axens markets the advanced F-T process as Gasel®.

e Paul Wurth’s advanced heater/reactor technology.

f thyssenkrupp Uhde’s gasification technology, PRENFLO will upgrade end-of-life wood waste and forest residues as feedstocks.

LITERATURE CITED

1 Courtaud, L., “How to monetize CO2: eFuels,” International Refining and Petrochemical Conference (IRPC), Houston, Texas (U.S.), October 2–3, 2024.

2 Caton, J., and Y. Bernard, “Unlocking the future of sustainable aviation fuels: Axens’ expertise in next-generation feedstocks and biofuel production,” Asian Downstream Summit, Singapore, October 23–24, 2024.

3 Axens, “Carbon capture: An introduction to the mature and emerging technologies,” March 23, 2022, online: https://blog.axens.net/carbon-capture-an-introduction-to-the-mature-and-emerging-technologies

4 Pigeaux, M., C. Salais, C. Streicher and J. Tourdjman, “Carbon capture and storage, a necessary tool to fight climate change—Solution for hard-to-abate emissions,” Axens whitepaper, online: http://gpc-whitepapers.com/uploads/media/Axens_WP_CCS_2022_EN.pdf

5 norsk e-fuel, “Norsk e-fuel contracts Paul Wurth (SMS group) to carry out a FEED study integrating Axens technologies for the first eFuel plant,” online: https://www.norsk-e-fuel.com/articles/partnership_paulwurth_axens

6 European Union Aviation Safety Agency (EASA), “Fit for 55 and ReFuelEu Aviation,” online: https://www.easa.europa.eu/en/light/topics/fit-55-and-refueleu-aviation

7 EDF, “EDF, Holcim, IFPEN and Axens join forces to participate together in the creation of the French eFuels air transport industry, with the "Take Kair" project, supported by Air France-KLM,” June 22, 2023, online: EDF, Holcim, IFPEN and Axens join forces to participate together in the creation of the French e-fuels air transport industry, with the "Take Kair" project, supported by Air France-KLM. - 2023/06/22 | EDF FR

8 “thyssenkrupp Uhde selected for Elyse Energy biomass-to-SAF project in France,” March 9, 2025, online: https://www.hydrocarbonprocessing.com/news/2025/03/thyssenkrupp-uhde-selected-for-elyse-energy-s-biomass-to-saf-project-in-france/

9 “Axens has acquired stakes in the BioTJet project for the production of SAF in France,” April 12, 2023, online: https://hydrocarbonprocessing.com/news/2023/05/axens-has-acquired-stakes-in-the-biotjet-project-for-the-production-of-saf-in-france

10 U.S. Congress, “H.R.1 - One Big Beautiful Bill Act,” online: https://www.congress.gov/bill/119th-congress/house-bill/1/text

ABOUT THE AUTHORS

Louis Courtaud is a technology engineer for Low Carbon Fuels with Axens’ Renewables Group for North America. He focuses on projects where Axens’ Fischer Tropsch process will be implemented. Courtaud handles early-stage development from feasibility studies through technology selection and basic engineering. He has more than 14 yrs of experience across the energy industry in both process design and project management, and holds an MSc degree in chemical engineering.

Yvon Bernard is a Business Development Manager with Axens’ Renewables Group. He is responsible for low-carbon and renewables projects, especially biofuels and bio-based chemicals. Before joining Axens, Bernard had experience in the upstream industry, working with Schlumberger in Southeast Asia and the Middle East. With Axens, he transitioned to the downstream business as a manager overseeing the startup of two major refineries and later moved to the Renewables group. Bernard holds an MSc degree in general engineering from the École Nationale Supérieure des Arts et Métiers in Lille, France, and completed a graduate program in Kunming, China.

Christopher Brunn is the Low Carbon Fuels Business Development Manager with Axens’ Renewables Group for North America. He plays a key role in advancing low-carbon fuel technologies and leads strategic initiatives in renewable fuels and sustainable process solutions. Brunn has more than 14 yrs of experience in business development across the chemical, food, energy, process and wastewater industries. His background combines technical knowledge and commercial insight to drive successful project development and long-term client partnerships. He holds a BS degree in chemical engineering.

Comments