Digital Exclusive: Turnaround digitalization with enhanced digital tools: A case study

Digital tools are transforming industries, and the industrial sector must adapt to remain competitive. Turnarounds (TARs), crucial periods for maintenance and upgrades, can benefit significantly from enhanced communications and data capture, real-time tracking and streamlined workflows through digitalization.

Digital tools are here to help with this transformation. There is no need to purchase non-customizable software to fill this digital process hole, making the digital tools fit your manufacturing facilities’ culture and processes, and not the other way around.

As a millennial, I was one of the last generations to not have computers or smart phones as a child. I grew up using pen and paper for solving math equations and even took a computer class on how to use a 3.5-in. floppy disc in the seventh grade. This quickly changed as I entered university, with the introduction of CAD software and computer-based learning in my early engineering classes. I expected to be working with computers in my future job; however, shortly after entering the workforce as an industrial manufacturing maintenance engineer, I realized that the industrial sector was far behind what was taught in university classes.

Fast forward another decade, and I was introduced to a build-our-own app program that allows for someone who is not familiar with computer programming to build custom programs and apps. Along with being able to build your own apps, I was also introduced to a dashboard tool that laid the groundwork for my digital transformation around TAR management. These programs that can make my work easier and automated were now readily available at my fingertips and built into my company’s information technology (IT) system.

The first digital tool program that I was introduced to was Power Bi. I wanted to publish a dashboard that contained some daily maintenance activities. This dashboard was simple, and I ended up teaching myself how to make the dashboard by watching YouTube videos and some similar Google searches. This simple dashboard ended up becoming a success within my business unit, allowing for better communication between multiple departments by sharing data that was just sitting in our department’s shared drive.

At the same time as earning a win for this communication through a Power Bi dashboard, I was tasked to be the TAR Manager for our site’s largest TAR. I had been through multiple TARs at this point in my career, and each had its own challenges with capturing data and keeping it organized, but this latest one was next level in size. Both the scope and budget were nearly double my previous TARs as a TAR Manager.

Prior to this project though, I was invited to join our sister manufacturing site overseas to assist with their TAR in Antwerp, Belgium. This assignment is where digital tools provided me with insights in creating a solution to build my own shutdown, TAR and outage (STO) software. STO software was something that I had been researching for 1 yr and considered multiple software applications to purchase an off-the-shelf program.

While working overseas, I was introduced to a company from the Netherlands that was in the process of making a STO for a manufacturing site in Belgium. The STO program was still in the infant stage of development, but it was functional, and it worked as a great pilot for a successful TAR. Due to the success of this pilot in Europe, I was able to carry this basic framework program and professional relationships I had developed to continue growing the MS Power Apps program in the U.S. for the larger TAR the following year.

The largest advantage of building any STO program in-house is having the control to build my company’s specific TAR workflow into the program without having to compromise any of the data that I want/need as the TAR Manager. Every TAR is different and, most of the time, its success is determined in how it is organized, managed and structured from a TAR Manager and Steering Team level. By developing and customizing digital tools, personnel can align the project with the site’s culture and provide the TAR team with the necessary data for a successful project.

CASE STUDY: MISSION 2024

In April of 2024, Kuraray America Inc.’s EVAL site used a customized tool built using the MS Power Platform in the preparation and execution of a site-wide TAR. This power app was called Shutdown, Transition, Outage Program (S.T.O.P. app), and input into this app started 12 mos. prior to the mechanical window. Moving into a digital world with the TAR space was a significant step for the organization. The company was even advised by TAR readiness assessment consultants that this was going to be a major challenge to develop a tool while planning and executing a TAR. However, the challenge and digital tool are the success stories of this TAR.

The 2024 TAR was the second TAR that the S.T.O.P. app was used globally within Kuraray, with the first pilot TAR in Europe. The Kuraray America TAR was > 100,000 manhours larger than the pilot TAR and included a 24/7 workforce for most of the execution. This was also the largest TAR the Kuraray America site had seen in terms of scope and workforce hours.

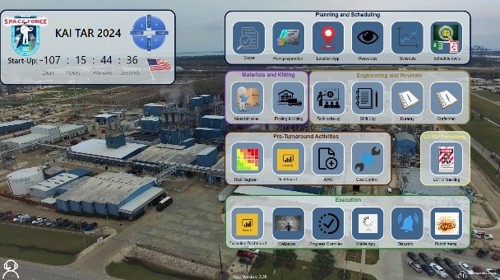

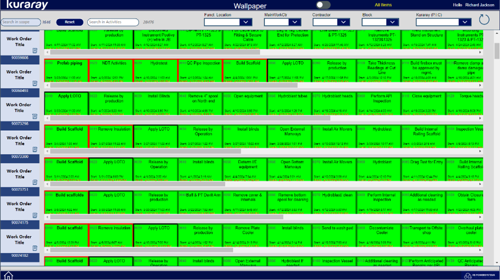

To achieve this increase in scope and execution, 18 additional digital tools/functional screens were developed and built for, improving from the original pilot of only five screens. These modified and/or developed screens included:

- Scope

- Worklist

- Planning work package development

- Work package development

- Materials purchasing

- Material management

- Lockout tagout tracking

- Risk management

- Cost control

- Execution reporting.

A view of the pilot app and the S.P.A.C.E. Force app for each TAR is shown in FIG. 1.

.

FIG. 1. A view of the pilot app V1 (top) and the S.P.A.C.E. Force app (bottom)

The end users for this app varied from management down to the foreman in the field. Data collection from all these individuals was key to communicating all the activities that a TAR encompasses.

The entire TAR process was planned and implemented outside of the normal computerized maintenance management system/enterprise resource planning (CMMS/ERP) programs used by the site. Even though the CMMS program had some capabilities and the S.T.O.P. app talks to the CMMS program, the S.T.O.P. app linked multiple other programs that all departments were using to unify the TAR efforts and process.

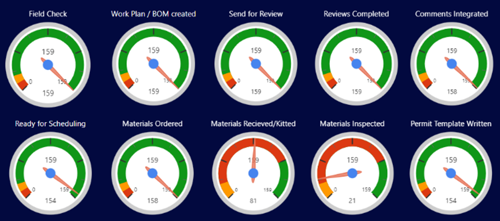

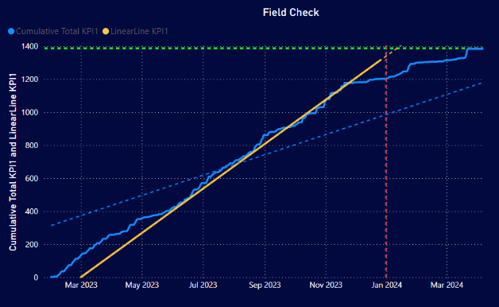

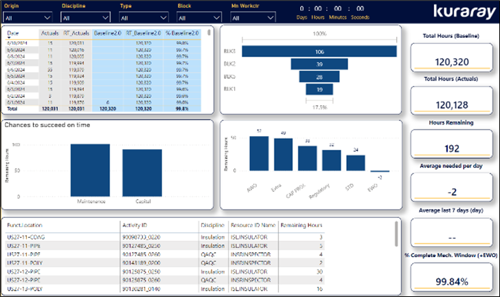

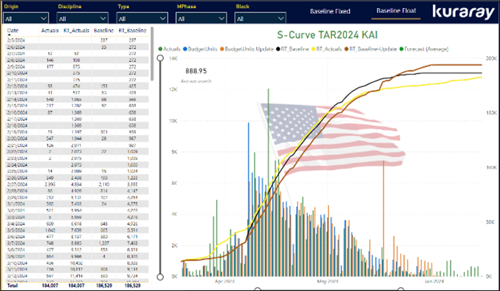

Planning was then visualized for all personnel and tracked utilizing Power Bi dashboards. Visibility of the planning efforts early in the process (T-15 or T-12 mos.) were something missing from past tracking efforts in TARs. Data collection on > 1,000 work packages on multiple stopgaps within the process was a manual entry in excel files and was very time consuming. By using digital tools for data entry as the TAR was being built and exporting this data to automatically update dashboards, TAR managers could manage the process without having loads of clerical work to keep up with excel files. Examples of these dashboards are shown in FIGS. 2–4.

FIG. 2. Planning tracking dashboard.

FIG. 3. Planning trends.

FIG. 4. Core team/steering team dashboards.

Gaining the trust for individuals to use this app was better than expected. Personnel embraced the opportunity to submit information into the program once it was understood that this communication is beneficial not only for their role within the TAR but shares communication across multiple departments and disciplines. Empowerment though communication was the highlight of the execution portion of the S.T.O.P. app.

End users such as the craft foremen, were key to provide updates on real-time activities in the field. Live updates could be completed using personal tablets. This data collection for work package completion reduced the need for the foremen to leave the production units and keep them in the field for managing personnel.

The execution input screen (FIG. 5) is how each foreman was able to input the status of their assigned work orders based on a 25% scale. This percentage complete was then sent directly to P6 to gain insight on what the foreman were seeing and managing in the field.

FIG. 5. Execution input screen.

Keeping craft foremen in the production units is important to the success of the TAR. Physically being in the field and in tune to what craftsmen are doing, along with being present and available for questions and redirections will increase time on tools and reduce overall schedule and cost. Boots on the ground and the supervision of these people are the key to a successful execution. Without proper management in the field, schedule and productivity will be a losing battle. With the S.T.O.P. app allowing for foremen to remain in the field, and with TAR management also being present more in the field and not having to update excel files or reports, showed stark improvement in time on tools and performance.

The largest success during the execution phase was within the production department. Process technicians (operators) appreciated the open communication that is normally missed between the maintenance, capital projects and production departments in normal daily activities, but especially within large projects like a TAR. Without having to attend update meetings, process technicians were able to quickly review dashboards and/or execution input screens to be informed about ongoing activities. This communication also assisted with cross shift changes to keep the communication constant and complete. This communication through shift change kept the momentum of the TAR going. The loss in productivity of the craftsmen and the operations team was minimized during these normally less than productive shift changes.

In addition to open communication with craftsmen and process technicians, TAR management was also kept informed with ongoing activities. Dashboards tracking manhours completed and manhours required were used, along with non-performance trackers such as permits written in a day or contractors onsite. All this data was available using dashboards to connect them all (FIGS. 6 and 7).

FIG. 6. Dashboard showing hours remaining.

FIG. 7. S-curve.

Lessons learned. TARs start and end with lessons learned. This thought process does not change with building STO programs for TARs. The good, the bad and the ugly only make the program stronger, as teams strive for continuous improvement. For the S.P.A.C.E Force case study, the integration of these lessons learned was detailed from the beginning by incorporating an electronic option to collect input during the TAR vis MS forms. This electronic collection was open to everyone, as it was intended to not limit the collection of input from anyone.

Collecting a plethora of lessons learned proved to be very successful. With so much success with the end uses, constructive feedback was very positive, with most recommendations for making the users’ experience even better. Examples of these recommendations included:

- Clearer schedule dates and times on the execution screen

- Easier scope addition for discovery workorders

- Integration of a single sign on solutions.

The most important item of all these recommendations was to gain the support of the site’s management to continue the development of the STO on/off TAR years or between TARs. Improvement and development from the lessons learned is key to continuing to grow your own successful digital STO program.

Overall, by using customized digital tools and properly developing these tools to align to the site’s specific culture and available resources, the S.P.A.C.E. Force TAR was completed safely and without any production delays. This tool is the real success story of this TAR. Without this tool, the site would have struggled to manage a scope of this size, as well as the personnel required for the project. By empowering all the end users with apps and dashboards at everyone’s fingertips, communication improved, morale was raised and a successful TAR was achieved!

Comments