Digital Exclusive: Monetizing stranded offgases from oil and gas facilities

A. R. HABIB and K. ALSHAMRANI, Saudi Aramco, Dhahran, Saudi Arabia

The objective of this article is to explore various viable solutions to monetize the stranded offgases produced in upstream oil and gas production and processing facilities. A brief description of available techno-commercial solutions and opportunities for the abatement of greenhouse gas (GHG) emissions generated in the downstream hydrocarbon processing industry—including petroleum refineries and petrochemical plants—is also discussed.

Despite significant economic losses associated with offgas flaring, it is now recognized as a major environmental concern. The 2024 Global Gas Flaring Tracker Report1 revealed that global gas flaring volumes rose from 139 Bm3 in 2022 to 148 Bm3 in 2023, an increase of approximately 7% year-over-year. Oil production remained relatively stable, resulting in an increase in global average flaring intensity.

The Global Flaring and Methane Reduction partnership estimated that in 2023, flaring released 381 MMt of carbon dioxide equivalent (CO2e), with a significant portion in the form of unburnt methane. Even more disturbingly, on a 20-yr basis, where methane has a global warming potential up to 80 times greater than CO2, increases CO2e emissions to 458 MMt.1 This level of CO2 exceeds the GHG emissions of entire countries like France, Italy or Australia, making flaring a significant contributor to global warming. In terms of dollar value, the flaring of 148 Bm3 of gas is estimated to be worth about $10 B–20 B (based on global average gas prices)1 and is more than the total gas consumption of Germany and France combined. Using 148 m3 gas volume for power generation would generate about 800 B kWhr, more than enough to meet the current power demand of Africa.1

Offgas flaring is one of the most challenging energy and environmental problems facing the world today. The increase in gas flaring in 2023 has highlighted the need for oil producers to accelerate efforts to end routine flaring and minimize methane emissions from oil and gas operations. The Global Gas Flaring Tracker Report1 emphasized the importance of transparent, accurate reporting on flaring and methane emissions, the implementation of low-emissions technologies for flare systems, and a shift in attitudes and policies to treat associated gas as a resource rather than a byproduct. Fortunately, there has been a 15% reduction in global flare volume over the last 10 yrs despite an increase in oil production.2,3 Importantly, more countries are taking stronger action to reduce flaring, and the World Bank announced an ambitious goal of zero routine gas flaring by 2030.1,4,5

In recent years, major operators and Leaders of G20 countries have been discussing ambitious targets for reducing emissions of GHGs. Globally, there are increasing efforts to reduce offgas flaring, notably through the World Bank’s Global Gas Flaring Reduction Partnership.1,4,5 In addition, the Global Methane Initiative (GMI) is an international public-private program—coordinated by the U.S. Environmental Protection Agency—that promotes the development of projects for the recovery and use of methane.

Offgas abatement projects offer real and tangible benefits such as eliminating routine flaring, GHGs reduction and recovered offgas can be re-used in plants as fuel gas, reducing the amount of natural gas purchased by the facility. In many instances, the offgas recovery and abatement projects have a short return on investment timeframe due to high energy costs. Therefore, this article is focused on how offgas recovery can be monetized by exploring multiple techno-commercial solutions to generate value from offgases while improving environmental impact.

Carbon emissions reduction. The implementation of offgas recovery and abatement initiatives will be of prime importance for long-term sustainability and competitiveness in the hydrocarbons business post introduction of GHG emissions targets, where operators would potentially be obliged or liable to report their current and target carbon intensities, decarbonization plan and strategy to meet goals. Carbon abatement/offset decarbonization projects can be defined as a tool to meet an oil and gas organization’s carbon key performance indicators (KPIs). Recent commitments by major oil producing countries toward decarbonization have increased the focus toward the development of low-carbon energy vectors.1,4

Saudi Aramco strives to reduce flaring across its business, with investments in flare gas recovery systems (FGRSs) and programs to improve asset integrity, energy efficiency, leak detection and repairs. As a signatory to the World Bank’s Zero Routine Flaring by 2030 initiative, the company shares best practices and knowledge with its peers so that its work has a broader and more positive impact. During 2022, Aramco’s flaring intensity decreased by 17% (4.601 ft3/boe in 2022 vs. 5.51 ft3/boe in 2021) due to significant investments, installations and improved operations of FGRSs across several facilities, and a reduction in routine and non-routine flaring.

Flaring in oil and gas and processing operations. Environmental and economic considerations have increased the use of FGRSs to minimize the amount of gas being flared. This article reviews some of the technologies for offgas recovery and utilization and identified promising technologies with capabilities of handling offgas.

Flaring processes can be classified into three groups:

- Emergency flaring

- Process or operational flaring and

- Production flaring.

Emergency flaring normally occurs for a short duration, involving a large volume of gas. Process flaring usually attributes with a lower rate, and plant failures from a few sm3/hr to thousands sm3/hr. Production flaring occurs in exploration and production sector of the oil and gas industry. Depending upon the nature of the reservoir (e.g., oil or gas), large volumes of stranded offgas can be combusted during the extended well testing or workover process. Offgas composition, flare header pressure and temperature, recovered offgas pressure and temperature, available utilities and plot space availability determines the implementation strategy of recovering this gas. Associated gases released during oil and gas production mostly contain high contents of methane, ethane and a small number of other hydrocarbons such as nitrogen, carbon dioxide (CO2) and hydrogen sulfide (H2S). Gas flaring from oil refineries and other downstream process operations will commonly contain a mixture of hydrocarbons and, in some cases, hydrogen (H2), as well.

FGRSs are rarely sized for emergency flare loads due to high capital expense associated with the required equipment. There are several technical challenges with an FGRS, including variable flowrates and compositions, low heating value and low pressure, and high contaminants levels of H2S, CO2 and other acid gases.

Generally, a FGRS is a skid-mounted vendor package that is installed downstream of the flare knockout drum. The FGRS package should have a design capacity of a maximum total routine daily flaring rate. The configuration of FGRS is dependent on the final destination of the recovered gas.

A conventional FGRS usually includes one or more gas compressors (FIG. 1). The recovered flare gas is at a low pressure (typically below 0.5 barg); therefore, this requires compression before it can be reused. Gas ejector-based FGRSs can also be employed based on the availability of the motive fluid and for plot space reduction.

FIG. 1. Views of conventional FGRSs, which tend to include one or more gas compressors.

The following details the applicability and implementation of FGRSs in the oil and gas sector.

Light gases generated in downstream processing.

- In downstream processing, the produced offgases are mostly comprised of light-end gases such as methane and ethane, which are routed to the fuel gas system after necessary treatment. Fuel gas is an important utility, which is usually required for fired heaters. It is also used as feedstock for petrochemical plants, H2 production and purge media, among others.

- In refining operations, hydroprocessing units produce light gases with high H2 content, which is very expensive, but an invaluable component. It can be recovered in a pressure swing adsorption (PSA) unit, or a membrane or cryogenic process unit to route the recovered H2 to the refinery’s H2 pool. PSA technology involves adsorbing impurities from a H2-rich feed gas onto a fixed-bed of adsorbents at high pressure. Subsequently, the impurities are desorbed into an offgas stream to produce an extremely pure H2 product to achieve H2 purity > 99.99%.

- A membrane-based separator system can be used to selectively separate H2 from other offgas components.

- In many cases, offgas contains significant amounts of saturated and unsaturated hydrocarbons, such as ethylene, propane, propylene, butanes, butylenes, pentanes and pentenes-plus mixtures. These gases can be recovered in/after treatment and can be used as petrochemical feedstocks or monetized.4,5,6

Upstream oil and gas exploration and production. Increased oil and gas production has resulted in an increase in associated gases production from stranded oil and gas production sites. To monetize associated gas from the oil and gas upstream sector is more challenging due to limited fuel gas requirement, remote locations, and unavailability of pipelines and process infrastructure. Stranded associated gas is generally not economically feasible to recover due to the unavailability of processing and pipeline infrastructure. The following strategies can be considered to monetize offgas after gathering and compressing:

- Recovered gases are used for reservoir management, depending on the specific subsurface requirements such as enhanced oil recovery (EOR) or injection into the wet gas reservoir to maximize condensate recovery

- Using gas as a fuel to generate steam to be injected into the reservoir for EOR.

- Collection and pumping to a nearby gas or multi-phase pipelines, flowlines or trunklines (bulk lines/gathering stations)

- Depending upon the composition of associated gas, liquified petroleum gas (LPG) can be extracted from associated gases prior to its usage for maximum value realization

- Using gas-to-liquid (GTL) technology to produce syncrude, naphtha, jet fuel, diesel, kerosene, lubes and other high value chemicals7,8

- Recovered gas can be converted into LNG—e.g., micro-LNG, mini-LNG or small-scale LNG liquefication skid-mounted plants9,10

- Utilizing recovered gas for captive power generation in gas generators (gas turbines or gas engines)

- Offgas can be used in gas-fired boilers to produce steam that can be used in industrial processes or to generate electricity in steam turbines, depending upon site requirements

- Utilizing the recovered gas to generate electricity (if there is no local power demand).

Gas monetization technologies. Several gas monetization technologies exist. Once the gas is recovered, it can be utilized in any of the applications mentioned above. The following are various gas monetization technologies:

- Gas flaring collection and compression. The collection and pumping of recovered gas to pipeline infrastructure (single or multi-phase) is a well-established and proven method to reduce flaring and venting. The implementation of this approach depends on the availability of pipelines and process infrastructure. The selection of compressor or ejector equipment, which is the main part of the FGRS, depends on many factors such as installed cost, process requirements, available plot space, utilities availability, efficiency, and operating and maintenance requirements. Different types of compressors can be used for an FGRS, such as dry screw compressors, sliding vane compressors, reciprocating compressors, liquid ring compressors and oil injected (or oil flooded) screw compressors (both single and dual screw). Ejector systems can also be utilized onsite on specific conditions and the availability of motive fluid media.

- Compressed natural gas (CNG). Offgas can be compressed to CNG after necessary gas treatment. CNG can be used to replace gasoline, diesel and LPG. CNG is a more environmentally friendly fuel. It is produced by compressing gas to < 1% of the volume it occupies at standard conditions. It can be stored and distributed in hard containers at a pressure of 20 MPa–25 MPa (2,900 psi–3,600 psi), usually in cylindrical or spherical shapes. CNG vehicles have been introduced in a wide variety of commercial applications, including cars, buses and trucks, as well as fueling drilling rigs or as backup fuel for generator sets, alleviating the need to import diesel. However, CNG is perceived as being a higher safety risk due to its high operating pressures.

- Liquefied natural gas (LNG). To tap stranded offgas from remote oil and gas fields where pipelines and process infrastructure are either not available or economically not viable, small-scale LNG plants are a good option. Mini- and micro-LNG facilities are commercially available in the capacity ranges of 0.5 MMft3d–15 MMft3d (20 tpd–300 tpd).9,11

LNG needs additional treatment to remove mercury, H2S, CO2, etc., whereas CNG may need slightly less treatment. LNG achieves a higher reduction in volume than CNG, as such, the (volumetric) energy density of LNG is 2.4 times greater than that of CNG or 60% of diesel. The volumetric efficiency (reduction of the gas volume relative to atmospheric conditions) is 150 to 300:1 for CNG compared to LNG at approximately 600:1. LNG is produced by condensing natural gas into a liquid by cooling it to approximately −162°C (−260°F). LNG is preferred for ease of storage and transport. It takes up about 1/600th the volume of natural gas in the gaseous state. LNG liquefaction is more complex than CNG compression and requires more capital investment vs. other monetization options.

LNG delivery technology is relatively mature and robust. Small LNG plants are now being built more economically. Various advantages of smaller LNG facilities are operational flexibility and reduced complexity, modular and mobile design, off-the-shelf equipment designs, reduced hazards due to reduced inventories, reduced footprint and scalability. Conversely, the disadvantages include higher capital costs to throughput ratio, higher operating costs and lower efficiencies.

Vehicle fuel LNG plants typically have capacities of 10 tpd–400 tpd and operate year-round. Note: 1,000 gal/d equals approximately 88 MMBtu/d–93 MMBtu/d, depending on LNG composition and conditions. Liquefaction system’s costs range from $1,500/MMBtu–$2,500/MMBtu in the case of moderately clean gas being liquefied. Typical LNG transport vehicles deliver 10,000-gal loads from LNG production facilities to refueling facilities.

Smaller vehicle sizes are available to transport LNG. For typical 10,000-gal deliveries in the U.S., the cost ranges from $1.50/mi–$3.00/mi. For example, a 200-mi trip of a truck carrying 10,000 gal at $2.50/mi is equivalent to $0.05/gal.12 - GTL. GTL is a proven technology, and advances in GTL technologies have recently enabled small-scale GTL and even micro-scale GTL to be operationally and potentially economically feasible over the last 10 yrs—several companies have developed mini-GTL and small-scale technologies that allow the conversion of offgas to synthetic oil (synoil), clean diesel and gasoline, methanol, DME (synthetic LPG), ammonia and other products. Several mini-GTL plants have been commercialized since 2014. These plants consume 2 MMft3d–25 MMft3d of natural gas, an excellent range for gas flare conversion. GTL is a catalytic process that involves the chemical conversion of natural gas (primarily methane) into high-quality fuels and chemical feedstocks such as synthetic crude, naphtha, jet fuel, diesel, kerosene, waxes, lubes, methanol and ethanol, among others.

Small-scale GTL plants can be classified in to three categories:

Small: Highly mobile and skid mounted plants scaled for flare sizes < 1 MMft3d.

Medium: These scale skids are suitable for flares from 1 MMft3d–10 MMft3d, but mobility decreases with size.

Large: These plants are designed for flare monetization above 10 MMft3d.

In comparison with other offgas recovery options such gas-to-electricity, natural gas liquids (NGL), CNG and LNG, mini-GTL requires lower gas volumes with minimum infrastructure and investment to monetize natural gas. Mini-GTL plants have several advantages: they can be deployed in mobile containerized small modular units that can be moved from one location to the other based on requirements, the skid-mounted plants have a smaller footprint, a typical mini-GTL skid produces 100 bbls of liquids for every 1 MMft3 of gas feed (depending on gas concentrations), they can offer good turndown capabilities and they require relatively less gas pretreatment or separation.7,13 Some of the commercially available data of small-scale GTL vendors are shown in TABLE 1.

TABLE 1. Overview of small-scale GTL vendors

|

Company |

Technology |

Products |

Feed gas/plant size |

|

Proton Ventures/Ammonia Casale |

N-Flex |

Anhydrous ammonia |

140,000 ft3d / 3 tpd |

|

GasTechno (mini-GTL) |

Partial oxidation |

Methanol, ethanol |

200,000 ft3d and above |

|

Maverick Synfuels |

GTL-FT |

Methanol and derivatives |

300,000 ft3d–1 MMft3d |

|

Infinium |

GTL-FT |

Diesel and syncrude oil |

1 MMft3d / 50 bpd |

|

Infra Technolgoy |

GTL-FT |

Diesel and methanol |

1 MMft3d / 100 bpd |

|

Oberon |

GTL |

DME |

1.3 MMft3d / 10,000 gpd |

|

Velocys |

GTL-FT |

Diesel |

2 MMft3d / 200 bpd |

|

EFT Technology |

GTL-FT |

Jet fuel |

2.5 MMft3d / 250 bpd |

|

Primus |

STG+ |

Methanol |

5 MMft3d |

|

GIE |

GTL-FT |

Diesel |

6 MMft3d–20 MMft3d/ 600 bpd–2,000 bpd |

|

Standard Alcohol |

Mixed-alcohol process |

Mixed alcohol |

500 bpd |

|

AUM Energy |

Unitel DEM technology |

DME |

10 MMft3d |

|

SGC Energia |

GTL-FT (XTLH) |

Diesel and jet fuel |

12 MMft3d / 1,100 bpd |

|

TIGAS |

MTG or STG |

Gasoline and DME |

15,000 bpd |

|

Compact GTL |

GTL-FT |

Diesel and others |

250,000 ft3d / 2,500 bpd |

|

ENG (compact) |

Calvert/OXEON Plasma reformer |

Diesel and others |

250,000 ft3d–20 MMft3d |

|

Metgas Processing Technologies |

STG+ |

Gas-to-propylene |

Small-scale |

- LPG and NGL extraction. Offgas is comprised of methane and NGLs. NGLs are mainly composed of ethane, propane, butane and heavier hydrocarbons. NGLs can be used in more valuable applications such as feedstock for petrochemical plants.

- H2 production. Recovered offgas can be monetized to generate H2. H2 production typically involves a large-scale reforming process using either methane or naphtha as a feedstock. There may be unique applications, especially at refineries where incremental increases in H2 production can be achieved by installing smaller-scale technologies. There are some emerging technologies to generate clean H2 from flare gas. One such technology, called LOOP, was developed by the UK-based company Levidian. LOOP is based on plasma technology. It uses a low-temperature, low-pressure process to crack methane into its constituent atoms–H2 and carbon–without the need for catalysts or additives. The carbon is locked into graphene, and H2 can either be used as a H2-rich blend or separated and stored for use in its pure form. It has been claimed that a single LOOP50 device using waste gas reduces CO2e by 100 tpy.

H2-Industries has developed a solution to convert environmentally harmful flare gas from oil production fields to clean H2 and solid carbon. H2-Industries uses pyrolysis technology to convert offgas into clean H2. The H2 production process from flared gas is free of CO2 emissions. Pyrolysis undergoes thermal degradation into smaller volatile molecules without interacting with oxygen. This technology can be delivered in self-contained mobile ISO containers and can be pre-assembled at the flare site. The process provides clean H2 bound in liquid organic hydrogen carriers (LOHCs). LOHCs are organic compounds that can absorb and release H2 through chemical reactions. LOHCs can therefore be used as a storage medium for H2. - Electricity production. Recovered offgas can be utilized to generate electricity, depending upon the onsite power demand and available infrastructure. Electricity can be generated by conventional gas turbines, gas engines or utilizing relatively smaller mobile micro-turbines. The microturbines’ power generation capacity ranges from 30 KW–10 MW by using the recovered gas that would have otherwise been flared or vented into the atmosphere. A set of small micro-turbines can offer a wide range of turndown with varying quantities of flare gas.14 Produced electricity can be used to satisfy local facility requirements or alternatively can be transmitted to the main grid.

Electricity generation implementation is based on the specific site conditions, available utilities, available space, configuration of power distribution network, etc. The efficiencies of electricity generation can be improved by considering cogeneration/combined heat and power and trigeneration/combined cooling, heat and power options based on techno-commercial viability.

RESULTS AND DISCUSSION

Case Study. The detailed techno-commercial evaluation and implementation of one of the compact GTL-based solutions has been studied for a typical remote oil production site. For the sake of high-level assessment, it is assumed that the oil and gas production site is remotely located, producing oil from stranded and randomly scattered oil production wells. The gas-to-oil ratio of the satellite oil reservoir is 300 ft3/bbl. The production of oil from each well is in the range of 2,000 bpd, as such, the production of gas from each well is 600,000 ft3d. The oil is processed in a central oil processing station which is located approximately 50 km away from the wells. The recovery of stranded associated gas is not economically feasible by a conventional approach, as there is a lack of pipelines and gas processing infrastructure. A small part of produced gas is being utilized in an oil processing station as fuel and purge gas, but a major portion of it is flared. The other potential gas recovery options (e.g., electricity production, reinjection, LNG) are also not feasible due to various technical and economic constraints. The construction of a permanent gas processing facility is not justifiable, as the life of these wells are short—i.e., 1 yr–1.5 yrs before they are depleted.

The technical viability and economic benefits of a mini-GTL-based solution offered was explored, and one of the most cost-effective and technically feasible technologies—providing the lowest capital and operational expenditures—was chosen.

The selected GTL process combines two advanced processes. The first is a non-thermal gliding arch plasma reformer to produce syngas. The reformer utilizes the gliding arc to create radicals, ions and excited states (translational, vibrational and electronic) within the vaporized feed stream to promote the breaking of chemical bonds to reform aromatics and hydrocarbons into syngas.

The second process improves the traditional Fischer-Tropsch reactor, with a proprietary reactor tube insert extrusion that provides improved temperature control throughout the reactor’s length.

The mini-GTL system produces 100 bbls of liquids for every 1 MMft3 of stranded gas feed, depending on gas concentrations. The mini plant can be operated and monitored remotely. The mini-GTL skid is very compact—the typical footprint of a 150-bpd skid is 4 m x 3 m x 5 m (l x w x h). The power requirement is 2.5 MW for every 500 bbls of oil production. The annual operation and maintenance costs are in the range of $500,000. The produced diesel contains no sulfur; therefore, it has a higher market value than regular diesel.

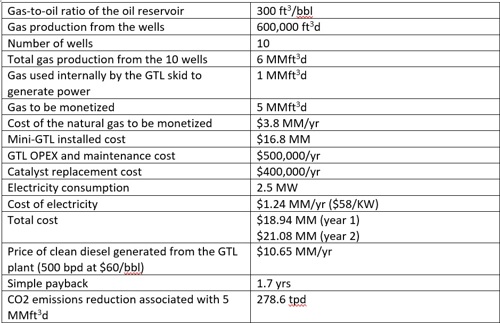

The production data, GTL costs and other relevant information is detailed in TABLE 2.

TABLE 2. Economics and data of the Case Study

Takeaways. The flaring of stranded gas is one of the biggest environmental challenges that generate GHGs and other emissions. These emissions have high global warming potential and contribute to climate change. The economic losses of gas flaring and venting are also significant. FGRSs reduce the need for continuous gas flaring and help mitigate GHG emissions and other harmful emissions such as sulfur oxides (SOx) and nitrogen oxides (NOx). Considerable monetization opportunities are available to recover offgas by employing a suitable recovery method. A cost-effective approach of utilizing GTL, LNG or other suitable options can generate significant revenue while helping to protect the environment.

LITERATURE CITED

1 World Bank Group, “Global Gas Flaring Tracker Report,” March 29, 2023, online: https://www.worldbank.org/en/topic/extractiveindustries/publication/2023-global-gas-flaring-tracker-report

2 World Bank Group, “Global gas flaring reduction: Technology overview—Utilization of small-scale associated gas,” February 2018.

3 World Bank Group, “Associated gas monetization via miniGTL: Conversion of flared gas into liquid fuels and chemicals,” January 2014, online: https://openknowledge.worldbank.org/entities/publication/b51afa19-51bd-59c6-9d91-3e80ebfdd0e8

4 McKinsey and Co., “Pathways to a low-carbon economy: Version 2 of the global greenhouse gas abatement cost curve,” September 1, 2013, online: https://www.mckinsey.com/capabilities/sustainability/our-insights/pathways-to-a-low-carbon-economy#/

5 Chan, H. W. and C. Cavness, “Minimizing the harm of methane emissions through flare reduction,” Crusoe, October 13, 2022, online: https://www.crusoe.ai/resources/blog/minimizing-harm-of-methane-emissions-through-flare-reduction

6 U.S. EPA, “Global methane initiative,” 2021, online: https://www.epa.gov/system/files/documents/2023-02/fy21-accomplishments-report-508.pdf

7 World Bank Group, “Associated gas monetization via miniGTL: Conversion of flared gas into liquid fuels and chemicals—Report 3,” July 2015.

8 PR Newswire, “Flare gas recovery system market size to increase by USD 1.40 Bn,” March 9, 2022, online: https://www.prnewswire.com/news-releases/flare-gas-recovery-system-market-size-to-increase-by-usd-1-40-bn--evolving-opportunities-in-very-large-capacity-flare-gas-recovery-system-segment--technavio-301497979.html

9 Newpoint Gas, “Monetizing flare and stranded gas: High BTU DPNG™ dense-phase natural gas,” November 2017, online: https://www.newpointgas.com/wp-content/uploads/2017/12/DPNG%E2%84%A2-Technical-Introduction-2017.11.27.pdf

10 Emam, E. A., “Gas flaring in industry: An overview,” Petroleum & Coal, December 2015.

11 World Bank Group, “Mini and micro LNG for commercialization of small volumes of associated gas,” October 2015, online: https://openknowledge.worldbank.org/entities/publication/e583518a-0bd0-5581-8f2c-ca60991fa575

12 NexentECA, “Fuel switching with NGLs/small-scale LNG (2005 program),” August 2005, online: https://www.nexanteca.com/reports/fuel-switching-nglssmall-scale-lng-2005-program

13 Snytnikov, P. and D. Potemkin, “Flare gas monetization and greener hydrogen production via combination with cryptocurrency mining and carbon dioxide capture,” iScience, February 2022.

14 World Bank Group, “Mini-GTL technology bulletin, Volume 6,” September 2019, online: https://documents1.worldbank.org/curated/en/634691575411174312/txt/Mini-GTL-Technology-Bulletin.txt

Comments