Yokogawa collaborates with Shell on robotics and AI technology for plant maintenance

Yokogawa Electric Corporation announced that it has formalized a long-term agreement with Shell Global Solutions International B.V. to integrate and further develop technologies for utilizing robots and drones in plant monitoring and maintenance. Under the agreement, Yokogawa will add an advanced machine vision tool called Operator Round by Exception (ORE), developed by Shell, into its own OpreX™ Robot Management Core. The enhanced software service will be made available by Yokogawa to customers in the energy, chemicals, and other industries.

ORE is a digital solution that uses machine vision and AI analytics to enable robots to autonomously perform a number of tasks in the operator round process, such as reading gauges and checking for leaks and machinery issues. It is the result of a two-year collaborative effort within Shell, which combined machine vision strategy with deep capabilities in the field of integrity management, remote site inspection, and corrosion management.

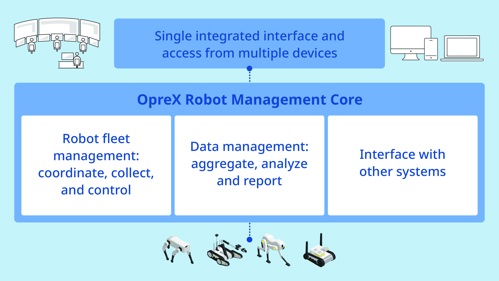

OpreX Robot Management Core is a key product in Yokogawa’s robot solutions. The software helps customers maintain their facilities in a safer and more efficient manner by integrating the management of various types of robots that perform plant maintenance tasks conventionally carried out by humans. When connected to a plant’s control and safety systems, the data acquired can be used to issue instructions to robots, thus enabling the first step to be taken toward autonomous plant operations. The addition of Shell’s ORE technology will significantly increase the number of use cases available to customers through OpreX Robot Management Core.

Moving forward, Yokogawa robotics operations will deploy at two Shell facilities as a pilot into how robotics and drones can deliver value through efficiencies in plant monitoring and maintenance.

This collaboration is the first key milestone for Yokogawa working alongside Shell in the collaboration space at the Energy Transition Campus Amsterdam, which was created by Shell in 2022 to provide a platform for collaboration between companies, societal organizations, governments, and universities to work on tomorrow’s energy solutions. Shell and Yokogawa have also agreed to collaborate on an aligned R&D roadmap to further develop and enhance the machine vision technology, ensuring continuous innovation and improvement. This collaboration underscores both companies' commitment to providing cutting-edge solutions to the energy and industrial sectors.

Comments