Ch0C gas boiler: A French consortium innovates for industrial decarbonization

The low-carbon gas boiler Ch0C has just been commissioned at the Villers-Saint-Paul site (Oise) after only three years of agile and collaborative work. Launched by a consortium of 16 stakeholders, this demonstrator aimed at industry has received support from ADEME and France 2030. This boiler is based on the integration and development of cutting-edge technological components. Driven by French companies, Ch0C marks the emergence of a new center of excellence. This industrial equipment enables a very high level of decarbonization at a competitive cost. Industrial boilers, across all energy sources, account for 23% of the total emissions from French industry.

Reducing direct CO₂ emissions from steam production by over 90%. The demonstrator is now operational, a major milestone in validating the results of the various technical studies conducted prior to the project. Starting today, multiple tests will be carried out under real conditions to optimize the performance of this 3 MW boiler. The Ch0C is a next-generation industrial boiler designed to facilitate the capture of CO₂ emitted during gas combustion. “Ch0C marks a turning point. We are no longer in the experimental phase: we now have a functioning equipment that will allow its users to significantly improve their carbon footprint.” announced members of the consortium.

Recovering or capturing CO2: when a constraint turns into an opportunity. The high-efficiency Babcock Wanson boiler is equipped with a state-of-the-art burner (Pillard OXYFLAM® 1 ) and a CO₂ capture and liquefaction system developed by Verdemobil Biogaz. The CO₂ is recovered directly at the boiler outlet instead of being released into the atmosphere, thus drastically reducing the carbon impact associated with the production of steam and hot water. The CO₂ can then be sequestered or recovered. Many industrial players require CO₂ in their processes, such as in the food or chemical industries.

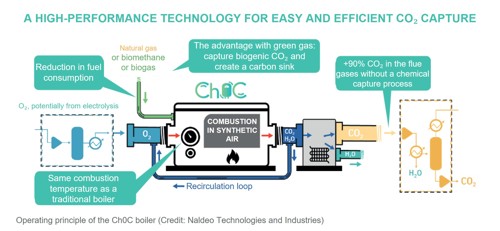

Optimizing performance to consume less energy. The innovation of the Ch0C boiler is based on the principle of oxy-combustion, which replaces air with oxygen during combustion. This process not only concentrates the CO₂ produced for capture and recovery but also improves the boiler’s performance. For the same amount of gas consumed, the boiler allows better use of the heat produced—a major expectation from industrial players.

A competitive technology closely monitored by industry players. The Ch0C boiler is expected to be commercialized as early as next year. In terms of total operating cost2 (excluding taxes), the Ch0C should offer a cost per kWh of steam produced up to 40% lower than that of an electric boiler and at least equivalent to that of a biomass boiler. Another advantage: compared to alternative solutions, the carbon impact is halved when the CO₂ is recovered. The higher the power, the more competitive the Ch0C boiler becomes. It will meet the high levels of decarbonization imposed on industrial players. Replacing 1,000 industrial boilers with this new boiler could prevent the emission of 4 million tons of CO₂ per year3 . A potential of 2,000 such boilers is identified in the French market for power ranges between 1 MW and 20 MW.

Effective decarbonization: 16 stakeholders supporting Industry. The consortium, led by Naldeo Technologies & Industries, brings together energy providers, equipment manufacturers, scientific experts, and industrial companies. Babcock Wanson, ENGIE Solutions, Fives, GRDF, NaTran, TotalEnergies, and VERDEMOBIL BIOGAZ are project partners. Agrial, Agro Mousquetaires, Bonduelle, Carboneo, Coca-Cola, Constellium, Eiffage Énergie Systèmes, and the University of Paris are observer members

Comments